Maintaining robust supplier relationships is pivotal in the procurement sector. Not only do these relationships shape the company’s image, but they also offer crucial benefits such as negotiating better prices, understanding supplier capabilities, and mitigating supply chain risks. This article delves into the nuances of effective Supplier Relationship Management (SRM) and provides actionable strategies to enhance these vital partnerships.

Understanding Supplier Relationship Management

Supplier relationship management (SRM) encompasses all the interactions and engagements a company has with its suppliers. It’s about nurturing these relationships to foster mutual benefits and ensure smooth operations. SRM is not just about managing contracts but about creating long-term, mutually beneficial relationships that help both parties grow and succeed.

Why Good Supplier Relationships Matter

Company Image

Positive relationships with suppliers reflect well on your organization, showcasing it as professional and reliable. A company known for maintaining good supplier relations is often seen as a trustworthy and stable business partner. This can enhance your reputation within your industry, making it easier to attract new business opportunities and partnerships.

Negotiation Leverage

Good rapport with suppliers can lead to better pricing and terms. Suppliers are more likely to offer favorable terms to businesses they trust and have a good relationship with. This can result in cost savings and better service levels, which are crucial for maintaining competitiveness in the market.

Capability Awareness

Knowing your suppliers’ full range of services, like recycling or product take-backs, can open new opportunities. For instance, a supplier who can handle product returns and recycling can help your company meet its sustainability goals, enhancing your corporate social responsibility profile.

Risk Mitigation

Strong relationships can help navigate and resolve supply chain disruptions efficiently. In times of crisis, a well-established relationship with suppliers can ensure quick communication and resolution of issues, minimizing the impact on your business operations.

Strategies for Effective Supplier Relationship Management

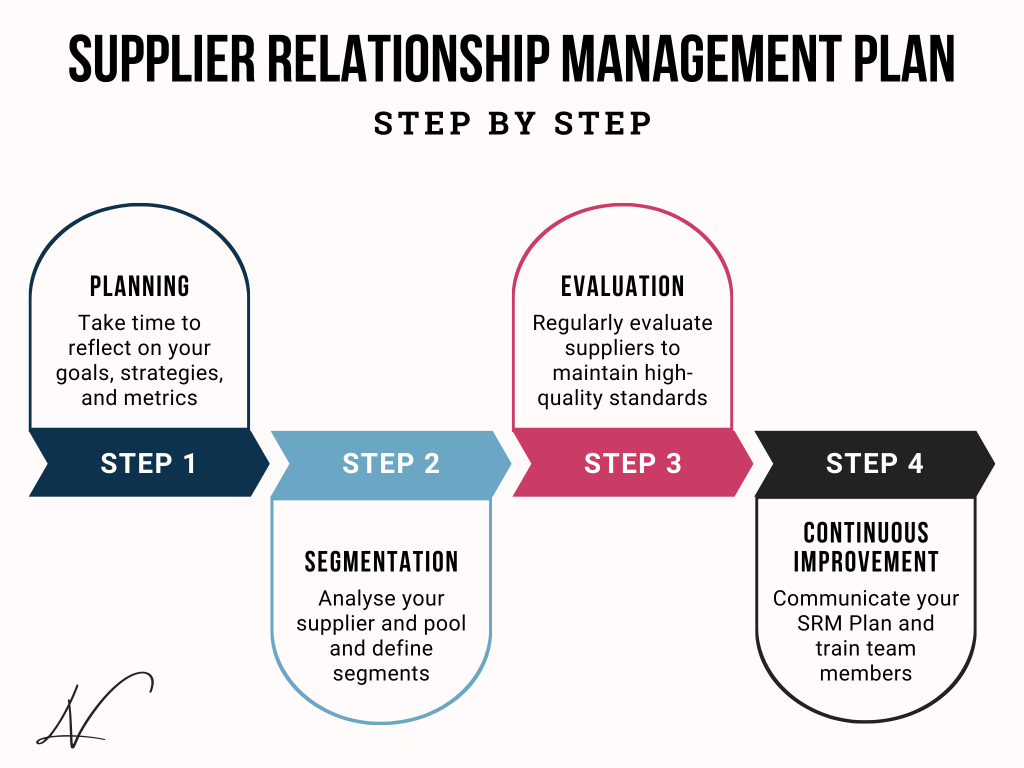

1. Make a Plan

Developing a comprehensive SRM plan is essential. This plan should outline your goals, strategies, and the metrics you will use to evaluate success. A well-thought-out plan acts as a roadmap, guiding your actions and ensuring consistency across the organization.

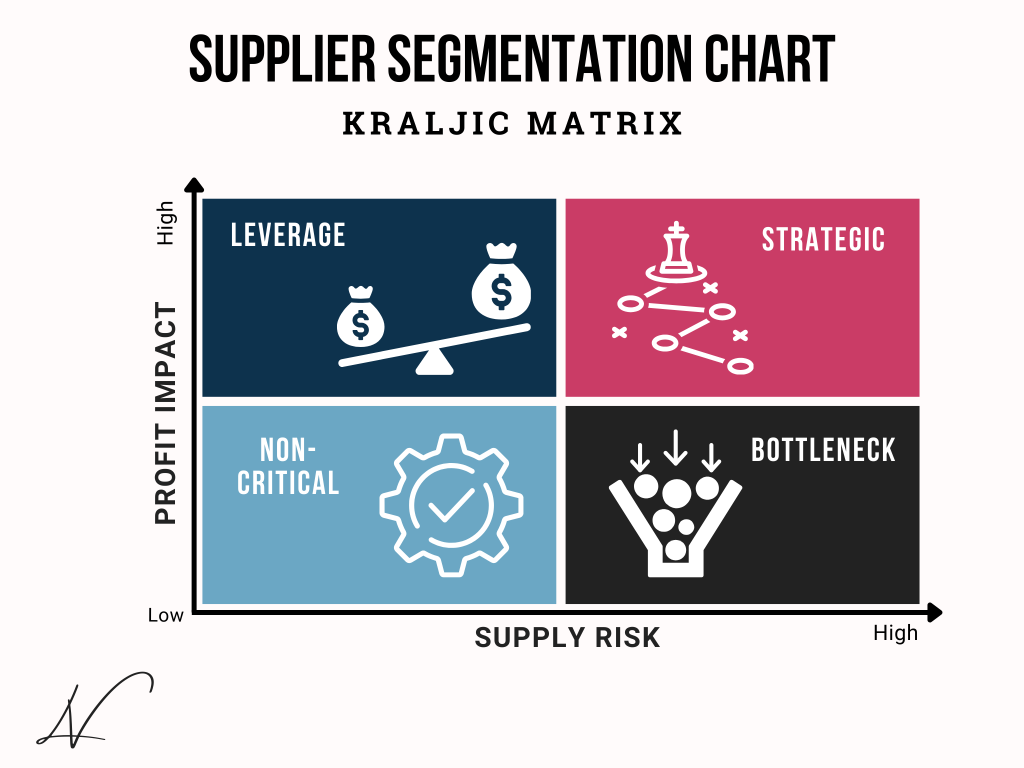

a. Segment Your Suppliers

Not all suppliers are created equal. Segmenting them helps in managing them more effectively. Key partners who are critical to your operations should be distinguished from those who can be replaced easily.

- Understanding Supplier Importance: Analyzing your supplier pool helps prioritize efforts and resources. Key suppliers should receive more attention and resources compared to those that are less critical.

- Long-term vs. Short-term Relationships: A strategic approach might involve long-term engagements with certain suppliers to ensure supply continuity, while maintaining short-term relationships with others to allow for business agility and flexible pricing. Long-term relationships build trust and reliability, while short-term relationships provide flexibility and adaptability.

Different methods exist to segment suppliers and I will present some of them on my next linkedIn Post. Stay tuned !

b. Create Strategies for Each Segment

For each segment, create tailored strategies. This might include different approaches for key suppliers versus less critical ones. Tailored strategies ensure that the specific needs and capabilities of each supplier are addressed, leading to more effective management.

Depending on the way you have segmented your suppliers, you will get advice on the different methods for each segment. For example, the Kraljic method advises that for non critical vendors you focus on rationalization, process automation and volume control.

c. Communicate and Execute the Strategy

Ensure that everyone in your organization who interacts with suppliers is aware of these strategies. A unified approach prevents miscommunications and aligns all efforts towards common goals. Clear communication is crucial for the successful implementation of SRM strategies.

For instance, imagine a new team member inadvertently revealing all your strategic goals to a supplier, jeopardizing your negotiating position. This underscores the importance of comprehensive internal communication and training. Ensuring that all team members understand the SRM plan and their role in it can prevent such mishaps.

To foster a deeper understanding and commitment, involve the entire team in the strategy development process. Encourage them to share their insights and perspectives. This inclusive approach not only enriches the strategy with diverse viewpoints but also ensures that everyone is on the same page about how to implement it effectively.

Tips for Better Supplier Relationships

1. Foster Mutual Understanding and Respect

Fair Terms and Transparent Processes

Ensure that all agreements are fair and transparent. Keep suppliers informed about how you select them and the criteria you use for evaluations. Transparency builds trust and shows that you value the supplier as a partner rather than just a vendor.

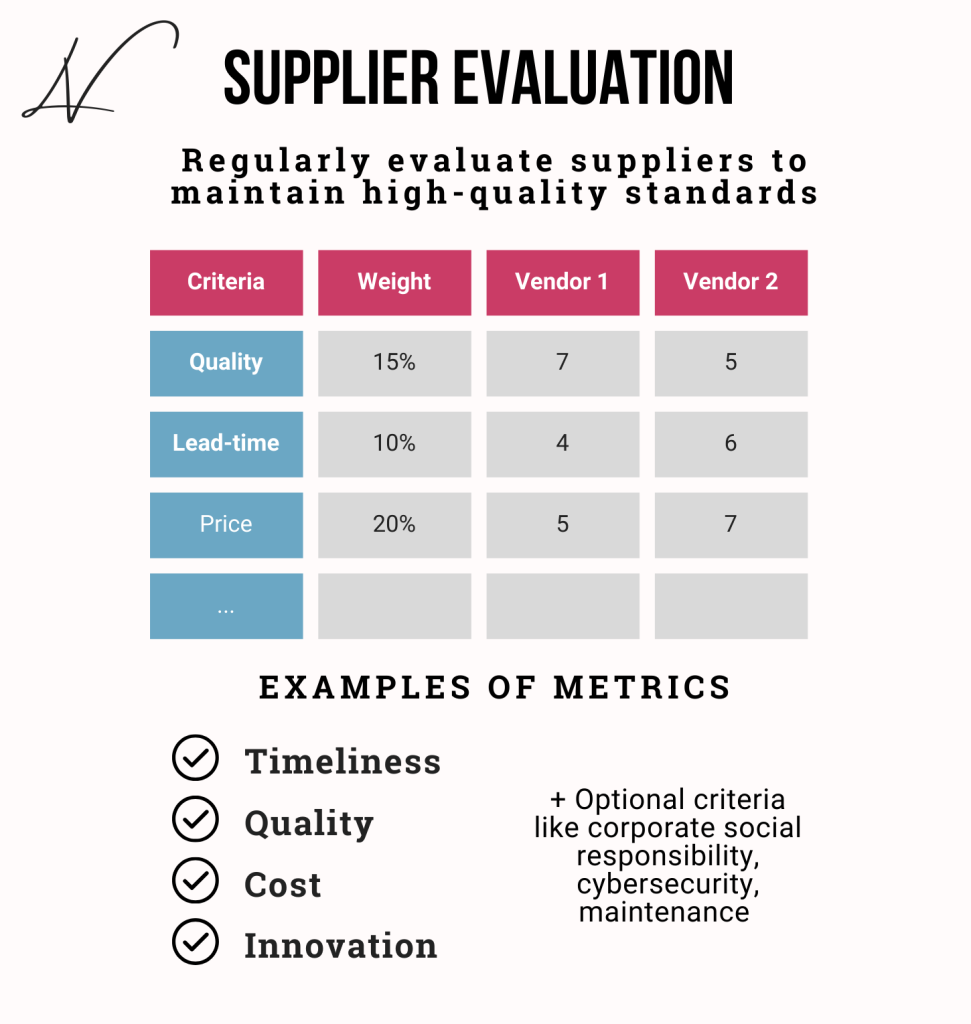

Regular Evaluations

Regularly evaluate suppliers to maintain high-quality standards, whether annually or semi-annually. Involve everyone who interacts with suppliers in the evaluation process, as their insights can be invaluable in assessing how effectively suppliers handle projects.

When selecting your evaluation method, consider metrics such as timeliness, quality, cost, and innovation. Additionally, incorporating optional metrics tailored to specific vendors—such as corporate social responsibility or cybersecurity for IT suppliers—can provide a more comprehensive assessment.

Regular evaluations not only help identify areas for improvement but also ensure that suppliers consistently meet your standards. This systematic approach fosters continuous improvement and strengthens your overall supplier relationships.

2. Effective Communication

Be an Active Listener

Listening to suppliers and reformulating their points ensures mutual understanding and minimizes conflicts. Active listening shows that you value their input and are committed to working together effectively.

Prepare Thoroughly for Meetings

Prepare questions and identify potential issues before meetings. Be ready for negotiations by knowing what you can and cannot accept. Thorough preparation demonstrates professionalism and respect for the supplier’s time.

Cultural Sensitivity in International Relations

Understanding cultural differences is crucial. For instance, when working with Chinese suppliers, silence often indicates refusal. Learning to navigate such nuances can prevent misunderstandings. Adapting to cultural differences shows respect and can enhance the relationship.

3. Treat Suppliers with Respect

Respect fosters trust and loyalty. Treat suppliers as partners rather than mere vendors. A respectful relationship encourages suppliers to go the extra mile for your business.

Involve Suppliers in Planning

Including suppliers in key initiatives or joint development projects builds stronger, more innovative partnerships. Collaboration can lead to innovative solutions and improvements that benefit both parties.

4. Transparent Evaluation Processes

Perform regular evaluations and communicate results clearly. This transparency helps suppliers understand your expectations and work towards meeting them. Clear communication of evaluation results ensures that suppliers know where they stand and what improvements are needed.

Implementing SRM in Your Organization

Implementing SRM requires a coordinated effort across the organization. Here are some steps to help you get started:

1. Gain Executive Support

Ensure that senior management understands the importance of SRM and supports the initiative. Executive support is crucial for securing the necessary resources and driving the SRM strategy across the organization.

2. Develop a Cross-Functional Team

Form a team with representatives from procurement, finance, operations, and other relevant departments. A cross-functional team ensures that all aspects of supplier relationships are considered and managed effectively.

3. Train Your Team

Provide training on SRM principles and practices to ensure that everyone involved understands their roles and responsibilities. Training should cover communication skills, negotiation techniques, and cultural sensitivity, among other topics.

4. Use Technology

Leverage technology to streamline SRM processes. Supplier management software can help track performance, manage contracts, and facilitate communication. Technology can also provide valuable insights through data analysis and reporting.

5. Monitor and Adjust

Regularly review your SRM plan and make adjustments as needed. The business environment and supplier landscape are constantly changing, so it’s important to stay agile and responsive.

Case Studies: Successful Supplier relationship management in Action

Case Study 1: Automotive Industry

An automotive manufacturer implemented a comprehensive SRM strategy, focusing on long-term partnerships with key suppliers. By involving suppliers in the early stages of product development, they were able to innovate more effectively and reduce time-to-market. The collaboration led to cost savings and improved product quality.

Case Study 2: Retail Sector

A large retailer segmented its suppliers based on criticality and value. By developing tailored strategies for each segment, they improved supplier performance and reduced risks. Regular evaluations and transparent communication fostered strong, trust-based relationships, resulting in better pricing and service levels.

Case Study 3: Technology Industry

A tech company facing supply chain disruptions due to geopolitical issues turned to SRM to strengthen relationships with alternative suppliers. By diversifying their supplier base and maintaining open lines of communication, they were able to mitigate risks and ensure continuity of supply.

Conclusion

While AI and automation are transforming many aspects of procurement, the human element in supplier relationship management remains irreplaceable. Building and nurturing these relationships are critical to a successful procurement strategy. Understanding your suppliers, treating them with respect, and maintaining clear communication will ensure strong, beneficial partnerships. By implementing these strategies, you can enhance your SRM practices, contributing to the overall success and resilience of your supply chain.

In this article, we explored the significance of supplier relationship management in procurement. From strategic planning and segmentation to effective communication and regular evaluations, each step plays a crucial role in building strong supplier relationships. By following these guidelines, procurement professionals can ensure they maintain high standards and foster mutually beneficial partnerships with their suppliers. As the business environment continues to evolve, the importance of strong supplier relationships will only grow, making SRM a critical component of any successful procurement strategy.

To learn more about optimizing your supplier relationships, book a free 30-minute consultation with me today!

![Read more about the article What is a purchasing policy and why do private companies need one? [WITH TEMPLATE]](https://lolitaverite.com/wp-content/uploads/2024/10/Purchasing-policy-300x225.png)